904L Stainless Steel Bar

Classification :

Stainless Steel Bar

Keywords :

904L Stainless Steel Bar

PRODUCT DETAILS

| Stainless Steel Bar | |

| Product Name | Stainless Steel Bar, Stainless Bar, SS Bar |

| Standard | GB, AISI, ASTM, DIN, EN, JIS |

| Available Grades | 200 Series: 201,202 |

| 300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H | |

| 400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 | |

| Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc | |

| Process | Hot Rolled, Cold Rolled |

| Sizes | Diameters: 6-300mm, Length:1-6m (according to customer's request) |

| Surface Treatment | NO.1, 2B, NO.4, BA, HL, Mirror |

| Inspection | SGS, TUV, BV, ABS, LR etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

| Finish | Description | Thickness (mm) | Width (mm) |

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.70 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.90 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.20 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.50 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.60 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2.00 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.50 | 914, 1219 & 1500 |

Packing And Delivery

Since its establishment, the company has been committed to the research and development, production and sales of steel pipes, providing high-quality steel pipe products and perfect solutions for global customers.

FACTORY PRODUCTION

Our factory covers an area of about 100,000 square meters and has a strong production capacity of 1 million tons of steel per year. We use the world's leading continuous casting and rolling technology to ensure efficient production and excellent quality of steel.

CUSTOMER VISIT

We value long-term cooperation with our customers and have won a good market reputation through continuous technological innovation and quality service. Tianjin Zhongxiang Steel Pipe Manufacturing Co., Ltd. looks forward to working with you to create a better future.

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

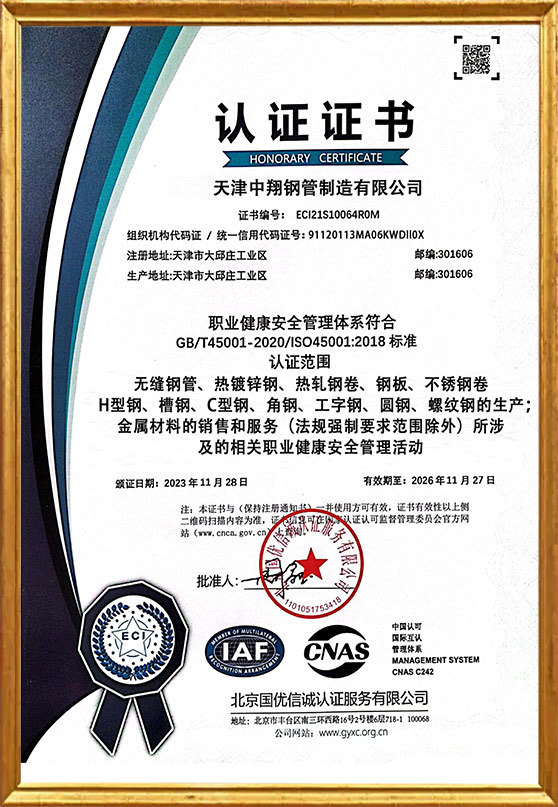

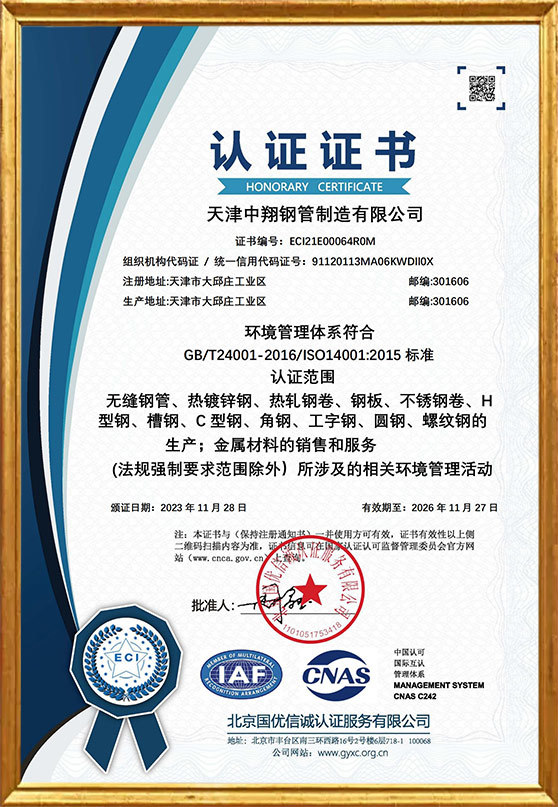

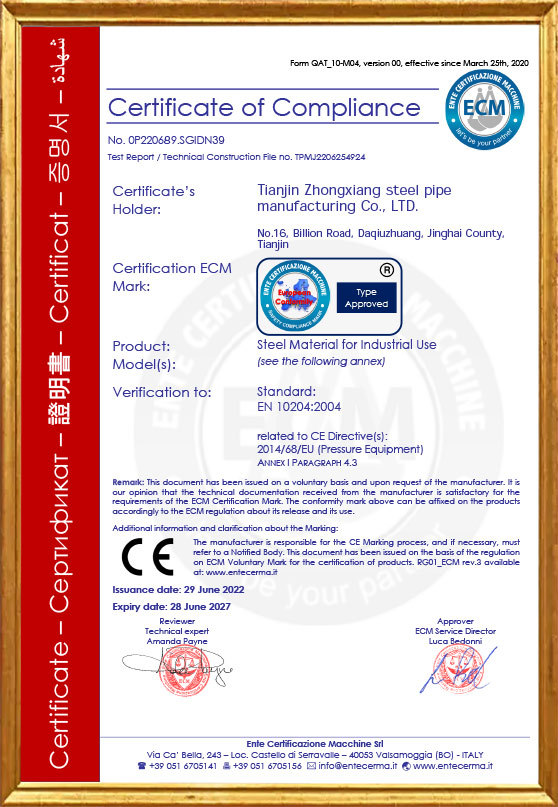

CERTIFICATION

We strictly follow the ISO 9001 quality management system to ensure stable and reliable product quality. Each batch of steel undergoes comprehensive quality inspection before leaving the factory, including chemical composition analysis, mechanical properties testing, etc., to meet the diverse needs of customers.

APPLICATION AREAS

Tunnel construction

Petrochemical

Bridge construction

Cross -sea bridge

FAQ

Q1: Are you a manufacturer?

Q2:Can we visit your factory ?

Q3: Do you have quality control?

Q4: Can you arrange the shipment?

Q5: How long is your delivery time?

Q6:How can we get the offer?

RELATED PRODUCTS

GET A FREE QUOTE

Leave your contact information and we will provide you with preferential quotes and free samples.