PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

EN10025 S235 Carbon Steel Pipes

S235JR (EN 1.0038) is an unalloyed structural steel commonly used in the building and construction industry. This steel grade is known for its excellent formability, weldability and strength, making it a popular choice for various applications.

American Standard ASTM A252 is pipe piling material standard that has been widely used in constructions and structural buildings. A252 specification includes three grades( 2, and 3), Grade 3 pipe piling material is the most used option.

Galvanized steel pipe has been dipped in molten zinc to help protect against corrosion. That layer of zinc protects the underlying metal from the weakening effects of weather and helps prolong the pipe’s longevity.

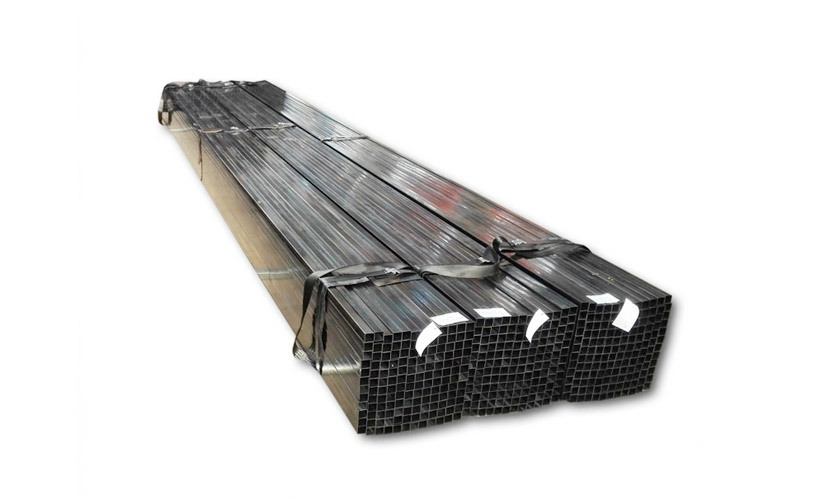

ASTM A519 Carbon Steel Square Tube

ASTM A519 Grade MTX1020 Carbon Steel Seamless Tubings are Low Carbon Steel Tubings with 0.15-0.25 % carbon content with combination of 0.70-1.00 % manganese. Low Carbon Steel Pipes are not as hard as hig carbon steel pipes,Though carburizing can increase its surface hardness.

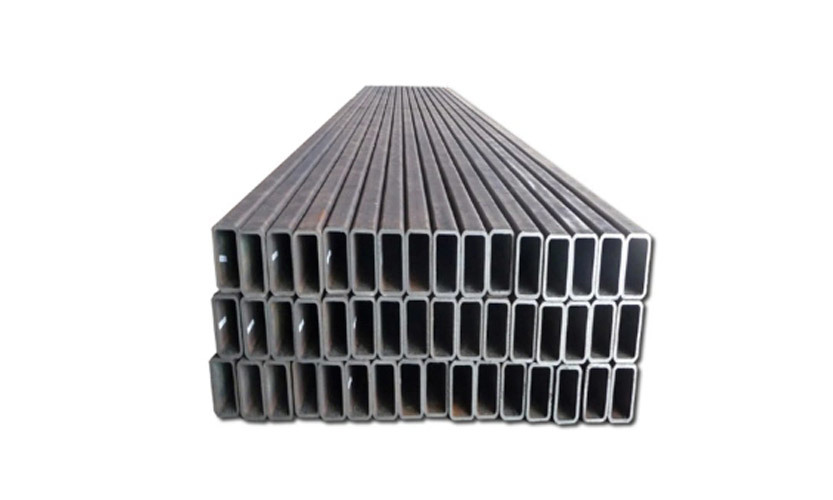

ASTM A213 Carbon Steel Rectangular Tube

ASTM A213 grade covers standard specifications for austenitic and seamless boilers, heat exchangers, and superheated vessels. The ASTM A213 Tube showcases excellent strength and outstanding corrosion resistance properties across an array of stress-induced setups.

API 5CT: From raw materials to products before delivery, flattening test, tensile test, impact test, tensile test and other relevant tests shall be conducted. API 5L: The production cost of stainless steel seamless pipe is obviously higher than that of welded pipe due to the micro alloying heating treatment process.

Incoloy alloys have more iron contents than inconel alloys. These alloys show outstanding corrosion resistance, strength, durability, and high-temperature stability.

The term nickel alloy refers to a metal that has nickel as one of its primary elements. Some types of nickel alloys are referred to as superalloys because of their superior oxidation and creep resistance, allowing them to be used at temperatures of more than half their melting points. Nickel alloys can be machined and welded but tend to pose some processing difficulties, as some alloys will work harden during machining, and their high melting points can make them difficult to weld.

Hastelloy is a kind of nickel based alloy. Hastelloy Alloy can be divided into two groups; one contains more molybdenum and the other contains more chromium. They all have excellent resistance to strong oxidizing solutions and high durability in reducing agents. Because of the low carbon content and less carbide precipitation during welding, they also have the ability to resist intergranular corrosion.

Monel refers to a group of nickel alloys that have copper as the main alloying element. In addition to these two primary metals, Monel alloys may also contain small amounts of iron, manganese, carbon, silicon, sulfur, aluminum, and titanium. The specific composition of a Monel alloy depends on its desired properties and applications. In general, Monel alloys are known for their high strength and resistance to corrosion in both fresh and saltwater while also having excellent high and low-temperature resistance.